“All that glitters isn’t gold,” the man said. Similarly, not all modern reception desks that look great online are shining examples of quality. For those of you who find the way your company is represented to be important, here are some things to consider when you are looking into buying a ready-made reception desk.

Few people who are on the market to buy a modern reception desk understand what they are buying simply by viewing a picture online. For quality-minded buyers, the biggest factors should be material and construction. With this information, you will be able to determine things like the lifespan of your reception desk, how it will wear, and how it will appear in your lobby area.

Most of the modern office furniture sold in this country comes in from abroad, and most of it is machine-produced from particleboard. It is shipped in parts and assembled by the end user. Let’s look at the materials and identify the advantages and disadvantages for you as a modern reception desk buyer.

Particleboard Reception Desks: Advantages and Disadvantages

Particleboard reception furniture originates with wood products. It is engineered by gluing and pressing small pieces of wood chips together with heat to form 4' x 8' boards. Because particleboard reception desks are so popular as office furniture, it is helpful to understand how they compare with other material options for your new modern reception desk.

Advantages:

Low Cost:

When considering a particleboard reception desk as opposed to plywood or solid wood, the greatest advantage is price. Generally, when you compare particleboard reception desks to those made from plywood or solid wood (which are hard to find in today’s reception-desk marketplace), particleboard desks will be half the cost or less of plywood or real wood. Low-cost, however, isn’t always the only cost when you consider the details.

Reception Desks, Ready-Made

Reception desks made from particleboard are generally produced by machine to the exact specifications of the predetermined furniture to be built. When reception desks are mass-produced in this fashion, the machines can be set to bang out parts fast, which adds to the low cost (by volume) production. This sets the stage to have your reception desk ready for you to buy with the click of a mouse.

Design Opportunity for Particleboard Reception Desks

Because reception desks produced from particleboard have a thin, preselected, laminated layer of plastic-like material in place as a surface covering, further support is given to reducing production cost. On the one hand, this approach saves production from having to laminate by hand; on the other, it will limit design options to colors and designs preselected by the reception-desk producer.

Conversely, with the selection of a plywood core reception desk, you can choose from hundreds of laminates and adhered veneers to make your reception desk more personal in design. The latter approach will add material quality and labor costs to your new modern reception desk.

Choosing Reception-Desk Material by Density

Pressing small, irregular pieces of wood together can save money because it allows the producer to use waste material. Due to the odd shapes of the pieces being pressed together, the process leaves airspace between them. The downside is that this material isn’t as strong as plywood, as it has less density. As a rule, the greater the density, the stronger the fastener hold.

Disadvantages

Less strength than other materials

Relocating a particleboard reception desk, whether across the room or across the city, may require a great deal of care. Simply because of low-density particleboard construction material, moving furniture can dislodge fasteners.

Short Lifespan, Reduced Durability

Another less-attractive aspect of particleboard reception desks is that they do not like humidity or moisture. Things like the heat and moisture from a cup of coffee on the desktop may leave a ring. A wet floor may cause swelling around the base area. Vacuuming the floor around the base of the desk can cause tiny pieces of wood to chip. For these reasons, the lifespan of a particleboard reception desk will be shorter than one made of other materials.

When doing the math and A-B-ing cost of a particleboard modern reception desk versus a plywood core desk over its lifespan, you will find a 2-3-year variable as opposed to 15-20 for a more durable core material.

The choice of reception-desk materials should come down to cost versus need. Maybe the company has a limited budget, and only needs a desk to get them through a couple of years to a healthier financial position. At that place in time, they will replace the desk with something more substantial. In this case, the question that need be considered is the following: is the desk worth buying twice?

Reception-Desk Support

As a rule, particleboard furniture does not lend itself to supporting much weight. You will need be careful not to put extreme weight on the furniture or sit on desktops, as they could crack or bow.

Company Representation

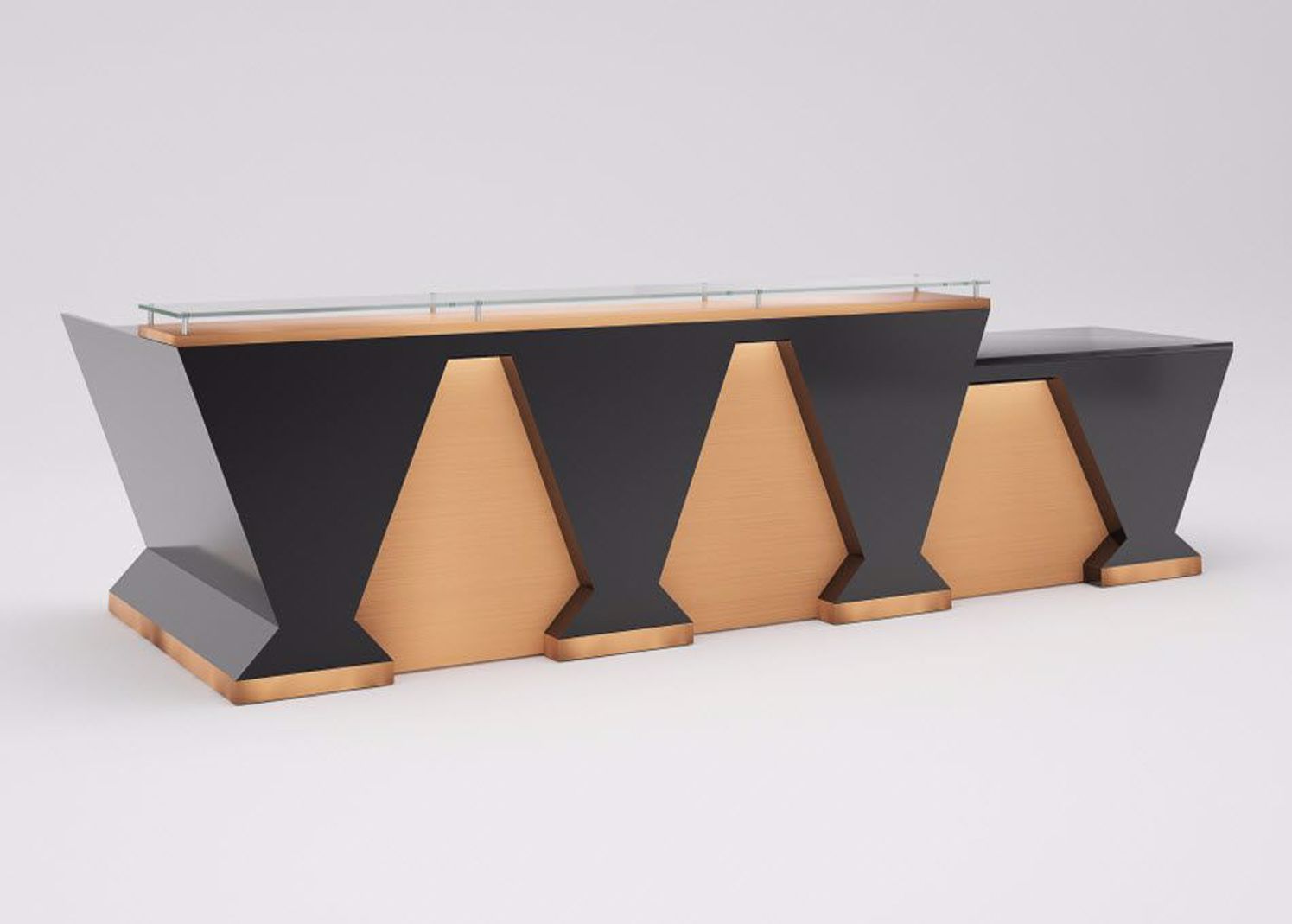

Modern reception desks made from particleboard are most often limited in design. Materials can’t bend or be reshaped into another look. This gives way to a very basic shape and a standard, commonplace appearance.

Most companies want to represent themselves as successful, even if they are not. Reception desks made from particleboard have a hard time appearing high-end. However, not every company has free cash to spend.

Environmentally-Friendly Furniture

The material used in the construction of this furniture is the same plastic resin that is used in making melamine break-resistant bowls and dishes. This makes disposal more difficult, because it doesn’t degrade well in the environment.

Conclusion

To put all of this in a nutshell, the advantages of a particleboard reception desk are simple: it is low-cost, and will be able to get a company by for a couple of years until they are able to upgrade.